What Types of Plywood Are Best for Cabinets?

When it comes to building or renovating cabinets, selecting the right plywood is crucial for ensuring durability, aesthetics, and cost-effectiveness. This comprehensive guide will walk you through everything you need to know about choosing the perfect plywood for your cabinet project.

Why Use Plywood for Cabinets?

Plywood has long been a favorite material for cabinet makers, and for good reason. This engineered wood product, consisting of multiple thin layers (veneers) glued together, offers an excellent balance of strength, stability, and affordability. Unlike solid wood, plywood is less prone to warping and shrinking, making it ideal for the varying conditions cabinets often face.

For the average homeowner, using plywood for cabinets can result in savings of 30-50% compared to solid wood alternatives, while still providing a durable and attractive finished product. With proper selection and installation, plywood cabinets can easily last 20-30 years or more.

What Types of Plywood Are Suitable for Cabinets

When shopping for cabinet plywood, you’ll encounter several specific types:

- Hardwood plywood: Available in various species, this type is perfect for visible cabinet surfaces. A 4×8 sheet of 3/4″ maple plywood typically costs between $50-$70.

- Softwood plywood: Ideal for painted cabinets or budget-conscious projects. A 4×8 sheet of 3/4″ pine plywood usually ranges from $30-$45.

- Marine-grade plywood: Extremely moisture-resistant, it’s suitable for bathroom cabinets or outdoor kitchens. Expect to pay $75-$100 for a 4×8 sheet of 3/4″ thickness.

- Cabinet-grade plywood: Specifically manufactured for cabinetry, it offers a balance of quality and affordability. Prices typically fall between hardwood and softwood plywood options.

Different Plywood Grades

Plywood is graded based on the quality of its face and back veneers, ranging from A (best) to D (lowest):

- A-grade: Nearly perfect surface, ideal for staining or clear finishes.

- B-grade: Minor imperfections, suitable for painting.

- C-grade: Larger knots and voids, best for hidden areas like cabinet backs.

- D-grade: Significant defects, not recommended for cabinets.

For most cabinet projects, AB grade (A face, B back) is a good choice, offering a balance of quality and cost. It typically costs about 15% more than BC grade but provides a significantly better finish.

How to Choose the Right Plywood for Cabinets

Strength and Durability

Consider the weight your cabinets will need to support. For example, a 36″ wide upper cabinet made with 3/4″ veneer core plywood can safely hold up to 100 pounds, while the same cabinet made with particleboard core might only support 60-70 pounds.

Moisture Resistance

Kitchens and bathrooms require different levels of moisture resistance. While standard interior plywood might suffice for most kitchen cabinets, bathroom vanities should use exterior-grade or marine-grade plywood to withstand high humidity levels.

Aesthetic Considerations

Think about your desired finish. If you’re planning to stain your cabinets, opt for hardwood plywood with an attractive grain pattern. For painted cabinets, a smooth surface is more important than grain appearance.

Cost-Effectiveness

While it might be tempting to choose the cheapest option, remember that cabinets are a long-term investment. Spending an extra $100-$200 on higher quality plywood for a typical kitchen can significantly extend the life of your cabinets and improve their appearance.

Environmental Impact

Look for plywood certified by the Forest Stewardship Council (FSC) if sustainability is a concern. FSC-certified plywood typically costs 10-15% more but ensures responsible forest management.

[Suggested image: A comparison chart of different plywood types and their characteristics. Search term: “plywood comparison chart for cabinets”]

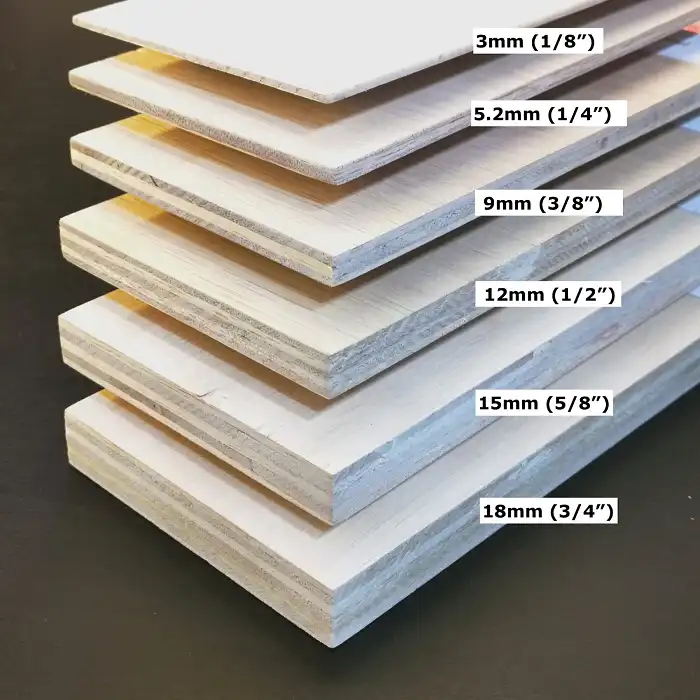

How Thick Should Cabinet Plywood Be

Different parts of a cabinet require different plywood thicknesses:

- Cabinet boxes: 3/4″ (19mm) is standard for most applications.

- Cabinet doors: 3/4″ for solid plywood doors, or 1/4″ (6mm) for panel inserts.

- Drawer sides: 1/2″ (12mm) minimum, preferably 5-ply or more for strength.

- Drawer bottoms: 1/4″ is usually sufficient.

- Shelves: 3/4″ for spans up to 36″, consider 1″ (25mm) for longer spans.

Remember, thicker isn’t always better. Using 1″ plywood instead of 3/4″ for cabinet boxes, for instance, adds unnecessary weight and cost without significant benefits in most cases.

Should Cabinet Plywood Be Moisture Resistant

The location of your cabinets plays a crucial role in plywood selection:

- For dry areas like kitchens with proper ventilation, standard interior plywood is usually sufficient.

- In bathrooms or laundry rooms, opt for exterior-grade plywood, which uses water-resistant glue and can withstand humidity levels up to 50% higher than interior plywood.

- For outdoor kitchens or extremely humid environments, marine-grade plywood is the best choice, capable of withstanding direct water exposure.

Regardless of plywood type, always apply a quality sealer or finish to enhance moisture resistance. A good water-resistant polyurethane can increase the moisture resistance of interior plywood by up to 80%.

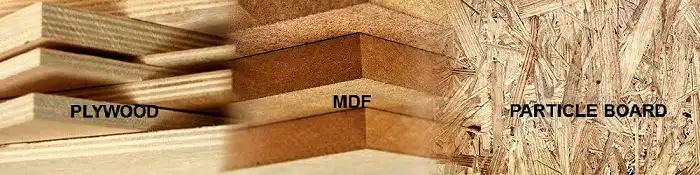

Plywood Alternatives for Cabinet Construction

While plywood is excellent for cabinets, other materials are worth considering:

- MDF (Medium-Density Fiberboard): Smoother than plywood, ideal for painted cabinets. It’s about 10-15% cheaper than comparable plywood but less moisture-resistant.

- Particleboard: The most affordable option, costing 30-40% less than plywood. However, it’s the least durable and moisture-resistant.

- Solid wood: The most expensive option, typically 2-3 times the cost of plywood. It offers unmatched beauty but is more prone to warping and expansion/contraction.

| Material | Cost (4×8 sheet) | Strength | Moisture Resistance | Best For |

| Plywood | $30-$100 | High | Good to Excellent | All-around use |

| MDF | $25-$50 | Medium | Poor to Fair | Painted cabinets |

| Particleboard | $20-$40 | Low | Poor | Budget projects, dry areas |

| Solid Wood | N/A (priced per board foot) | High | Fair | High-end, custom cabinets |

Verdict

When it comes to choosing the perfect plywood for your cabinet project, consider it a balancing act of practicality and aesthetics. Start by evaluating your cabinet’s environment – will it face high humidity or remain in a dry area? This will guide your choice towards moisture-resistant options if needed.

Next, envision your ideal finish, whether it’s a natural wood look or a painted surface, as this impacts the type of plywood you’ll select. Of course, your budget plays a crucial role, so weigh the costs against the long-term benefits of higher-quality materials.

Once you’ve made your selection, remember that proper handling is key to success. Use sharp tools, apply edge banding for a polished look, and always pre-drill to prevent splitting. Allow your plywood to acclimate before use, and don’t skimp on the finish – even for hidden areas.

With these considerations in mind, you’ll be well-equipped to create durable, beautiful cabinets that stand the test of time.

Frequently Asked Questions

What is BWP-grade plywood?

BWP stands for Boiling Water Proof. This grade of plywood is manufactured using phenol formaldehyde resin, making it highly resistant to moisture and suitable for exterior applications. While not always necessary for indoor cabinets, BWP grade plywood is an excellent choice for areas with high humidity or potential water exposure, such as bathroom vanities or outdoor kitchen cabinets.

Is MDF or HDF better for kitchen cabinets?

Both Medium-Density Fiberboard (MDF) and High-Density Fiberboard (HDF) can be used for cabinets, but they have different characteristics:

- MDF is denser than regular plywood but less dense than HDF. It’s excellent for painted cabinets due to its smooth surface.

- HDF is even denser and stronger than MDF, making it more resistant to dents and scratches. However, it’s also more expensive.

For most kitchen cabinets, MDF is sufficient and more cost-effective. HDF might be preferred for high-wear areas or if you’re looking for extra durability.

What color is best for cabinets?

While this is largely a matter of personal preference and current design trends, some colors have proven to be timeless choices for cabinets:

- White: Creates a clean, bright look and makes spaces appear larger.

- Natural wood tones: Offer warmth and a classic appeal.

- Gray: A modern neutral that complements many design styles.

- Navy blue: Adds depth and sophistication, especially in larger kitchens.

Remember, lighter colors can make small spaces feel more open, while darker colors can add drama and coziness to larger areas.

What is high-quality plywood?

High-quality plywood typically refers to plywood with the following characteristics:

- More plies (layers) for increased strength and stability.

- Higher grade face veneers (A or B grade) for better appearance.

- Minimal core voids or gaps.

- Use of hardwood species for face veneers.

- Strong, water-resistant adhesives between layers.

Cabinet-grade or furniture-grade plywood are terms often used to describe high-quality plywood suitable for fine woodworking projects.

How to choose plywood?

When choosing plywood, consider these factors:

- Intended use (e.g., cabinets, furniture, structural)

- Required strength and durability

- Moisture exposure in the intended location

- Desired appearance (if visible)

- Budget constraints

- Environmental certifications (if important to you)

Always inspect the plywood for defects like warping, delamination, or large knots before purchasing. When possible, buy from reputable suppliers who can provide detailed information about their products.